Complex workmanship,

maximum attention to detail.

We use cutting-edge technologies and services that allow us to carry out complex processes with maximum precision and in short times.

Warehouse

We have a 500 m2 warehouse that allows us to store both a large number of raw materials to respond to customer needs, as well as finished and repetitive products to be used for managing scheduled deliveries. All this, without slowing down ordinary production.

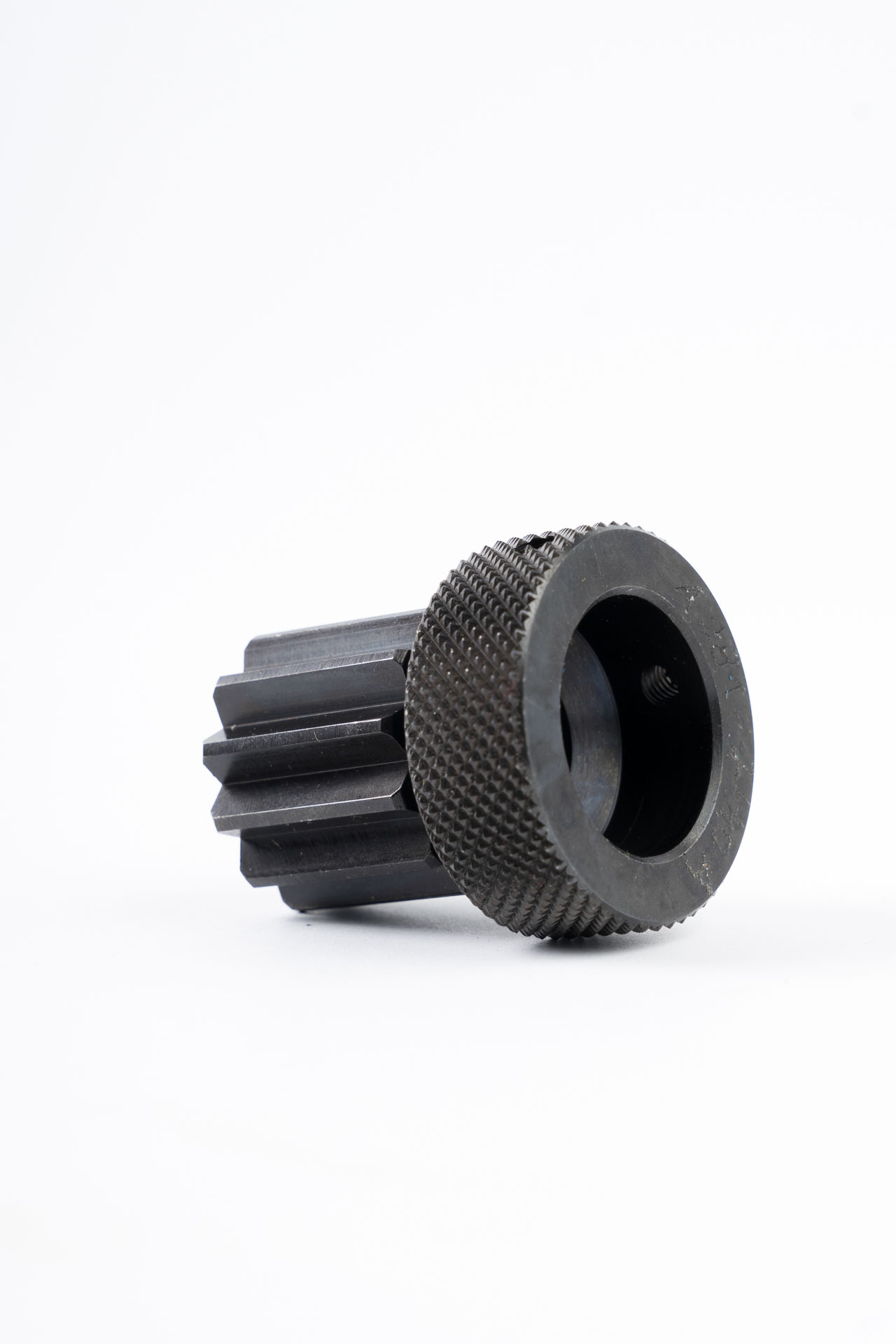

Three five-axis machining centers

These machines allow us to perform highly precise work without the help of an operator, reducing production times and responding to customer emergencies 24 hours a day.

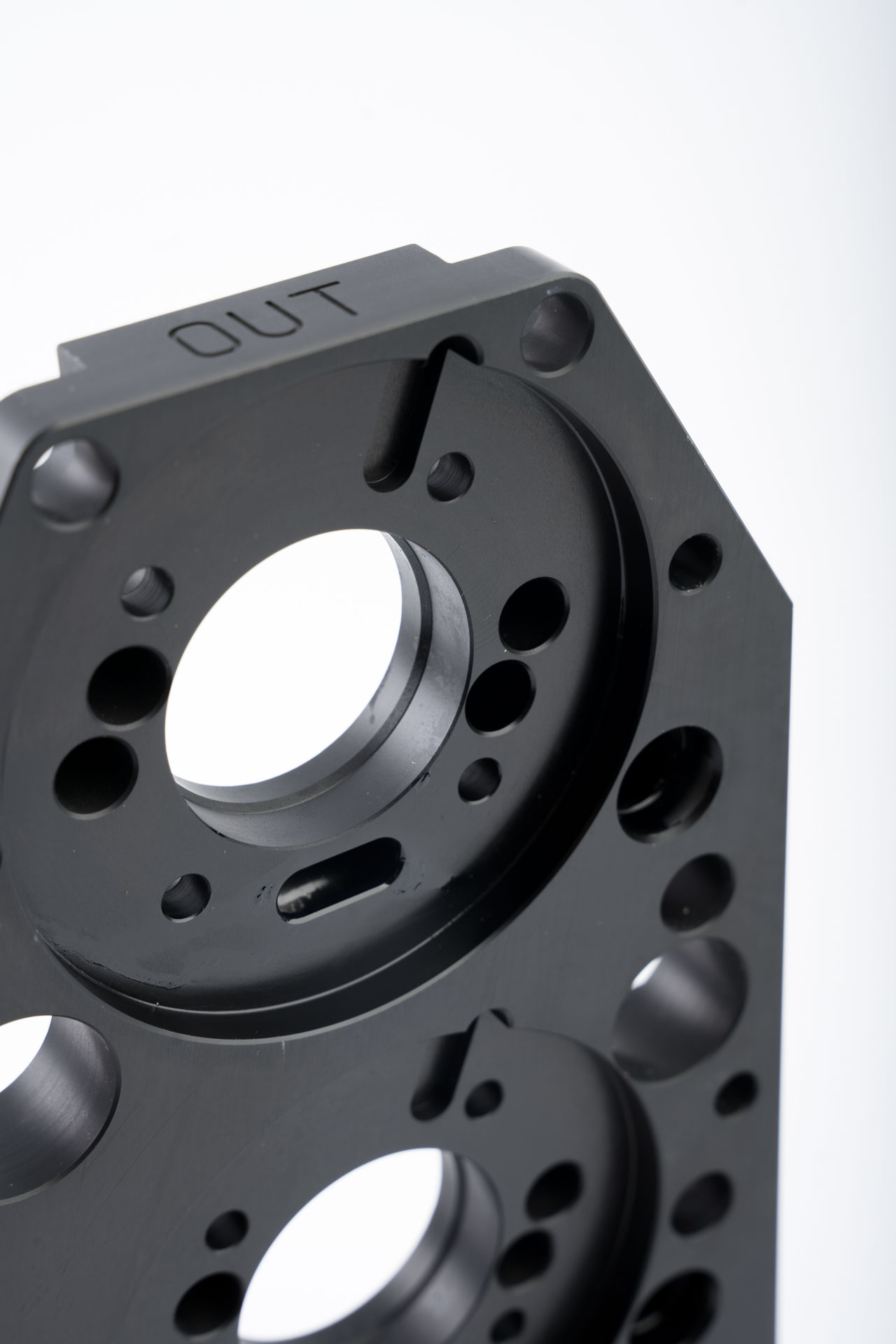

CMM with PH20 system

The coordinate measuring system (CMM) with PH20 technology guarantees extremely accurate quality control, before shipping the goods, verifying that each component respects the required tolerances with maximum precision.

24 hours a day.

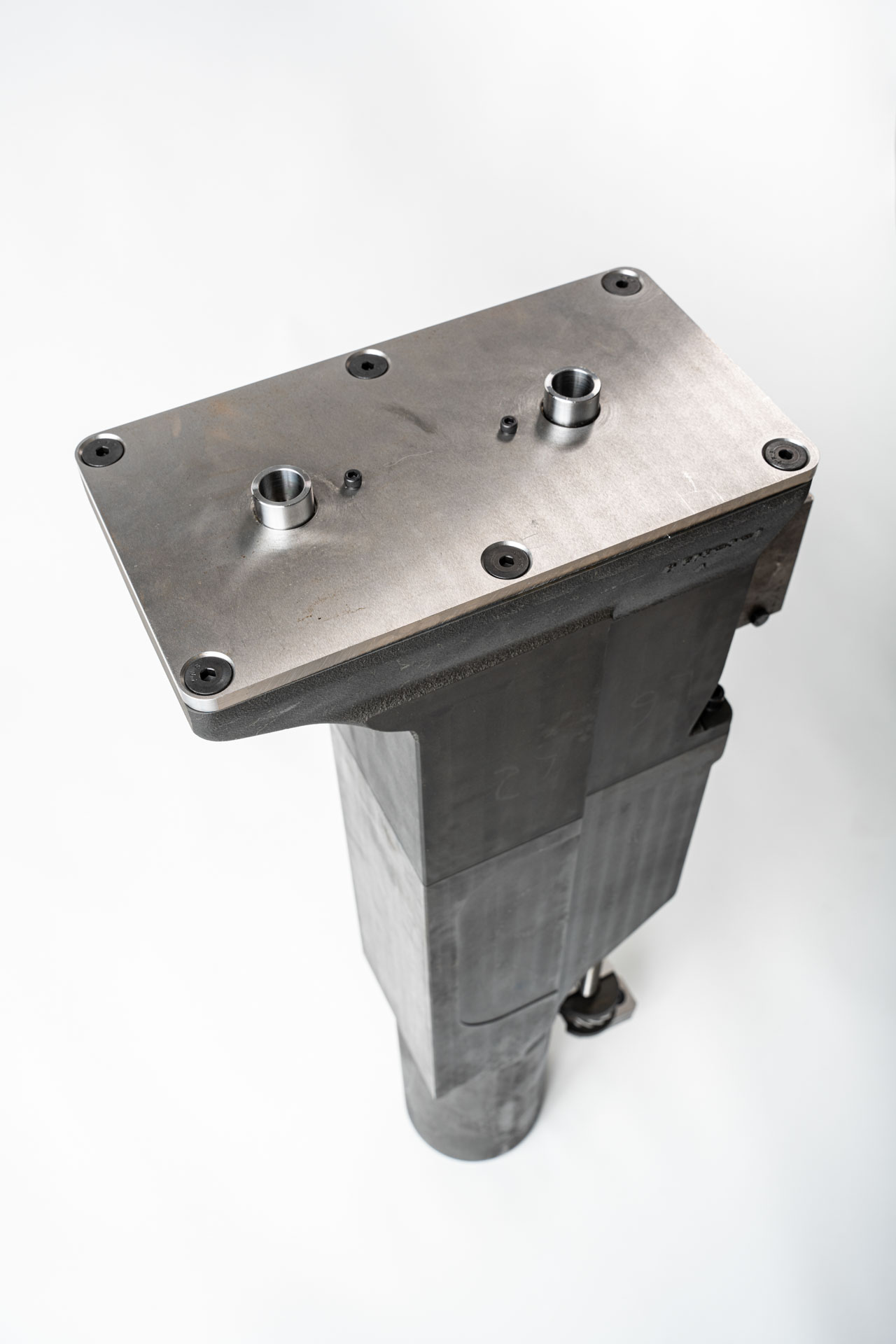

Anthropomorphic Robots

We select highly efficient tools for our machine park that are capable of performing extremely detailed work. Among these we have the Lang Robotrex, a latest-generation 6-axis robot capable of operating different products in a single production cycle.

Machinery Park

| TURNING | STEP OF BAR | DIAMETER TURNING | LENGTH TURNING | INFO |

|---|---|---|---|---|

| BIGLIA 620 | Ø70 | 360 | 620 | |

| BIGLIA 501 | Ø70 | 350 | 500 | |

| BIGLIA 301 | Ø40 | 220 | 350 | |

| BILLA 301 + MAGAZINE LNS | Ø40 | 220 | 350 | Magazine + bar feeder for medium-large series |

| LEADWELL LTC-20 | Ø65 | 320 | 520 | |

| LEADWELL LTC-25LM | Ø85 | 450 | 1000 | Motorized turret |

| LEADWELL LTC-25 | Ø65 | 320 | 520 | |

| BLEADWELL LTC-25LM | Ø70 | 360 | 620 | Motorized turret |

| MILLING | X | Y | Z | INFO |

|---|---|---|---|---|

| FEELER VMP-65 (1650) | 1650 | 800 | 800 | |

| NIKKEI 1250 | 1250 | 610 | 610 | |

| FEELER VMX 1020 | 1020 | 520 | 560 | |

| 2 - FEELER NBP 1000 | 1020 | 520 | 560 | |

| 4 - FEELER VMP 40 | 1020 | 520 | 505 | 4 axes high speed |

| FEELER VMP 30 | 760 | 420 | 510 | |

| LEADWELL BC-600 | 1100 | 610 | 650 | 5 continuous axes with Ø600 table rotating 360° |

| ROBOTREX | 32 pallets | Anthropomorphic robot operating 24 hours a day, capable of repeating programmed movements with different parts | ||

| DMG-MORI DMU 70 | 750 | 600 | 520 | 5 axes with -10°+95° tilting table with 360° "C" axis |

| REMACONTROL RAFFAELLO R5A6 | 650 | 600 | 650 | Pallet dimensions 320x320 |

| RACK TYPE PALLET CHANGE | 15 pallet |

| 3D PRINTING | X | Y | Z | |

|---|---|---|---|---|

| ROBOZE PLUS PRO | 300 | 250 | 220 | |

| FORMLABS FUSE 1 | 165 | 300 | 165 | |

| FORMLABS FUSE 1+30W | 165 | 300 | 165 | |

| MARKFORGED X7 | 270 | 330 | 200 | |

| BAMBULA X1C | 256 | 256 | 256 | |

| NEXA3D XIP PRO | 163 | 410 | 292 | |

| FORMLABS FORM 3 | 145 | 185 | 145 |

| CMM TESTING | X | Y | Z | |

|---|---|---|---|---|

| COORD3 10.7.5 Y | 1000 | 500 | 500 | PH20 head |